The Environmental Impact of 3D Printing: Myths vs. Facts

- By -Duke

- Posted on

- Posted in 3D Printers

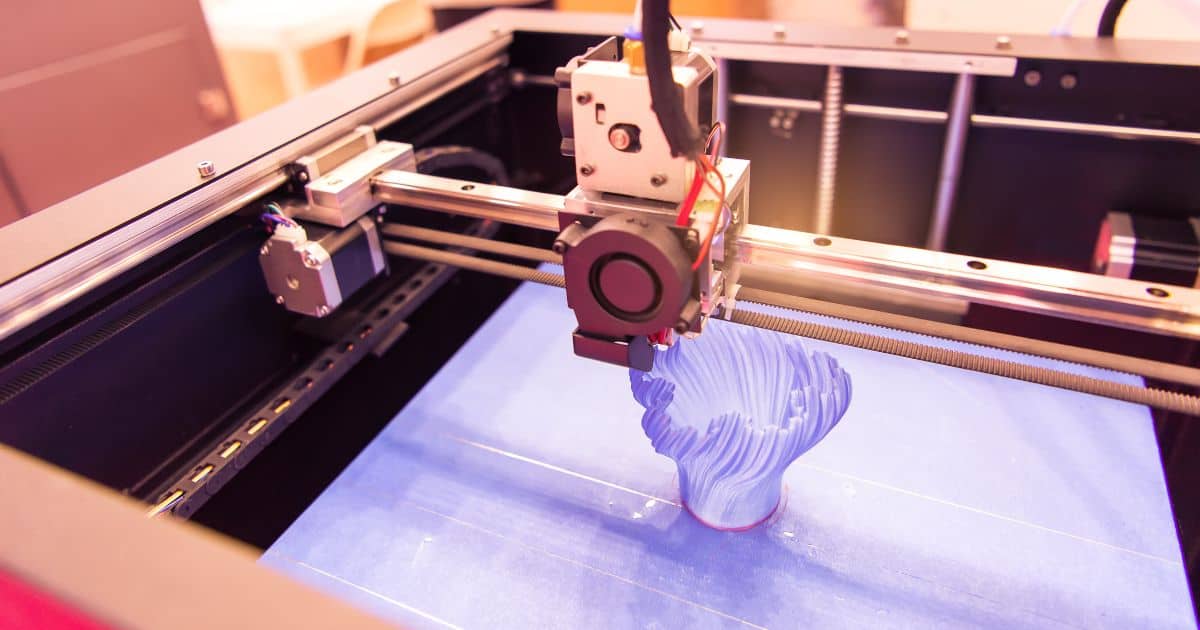

3D printing, also known as additive manufacturing, has revolutionized industries by offering a more efficient and customizable approach to production. However, its environmental impact is often debated. Some believe that 3D printing is a sustainable and eco-friendly technology, while others argue it may contribute to environmental harm. In this article, we’ll address common myths and present the facts to provide a clearer understanding of the environmental implications of 3D printing.

Myth 1: 3D Printing is Always More Sustainable Than Traditional Manufacturing

One common belief is that 3D printing is inherently more sustainable than traditional manufacturing methods like injection molding or machining. While it’s true that 3D printing can reduce material waste by using only the required amount of material, it doesn’t necessarily mean it’s always more environmentally friendly. Traditional manufacturing techniques, such as injection molding, can produce large quantities of items more efficiently, with less energy consumption for mass production. In contrast, 3D printing often uses more energy to produce smaller quantities, especially when printing large objects, which can offset its benefits.

Fact: Energy Consumption Can Be High

The energy consumption of 3D printers can be significant, especially for high-resolution or industrial-scale printing. This energy usage depends on the type of material, the printer itself, and the printing process. For example, certain 3D printing technologies, like selective laser sintering (SLS) or fused deposition modeling (FDM), often require long print times, which leads to higher electricity consumption. Therefore, while 3D printing can reduce material waste, its energy demand might offset its environmental advantages, particularly when considering the energy sources powering these printers.

Myth 2: 3D Printing Uses Harmful Materials

Another misconception about 3D printing is that it always involves harmful or toxic materials that contribute to environmental degradation. Many believe that the plastics used in 3D printing, such as ABS (Acrylonitrile Butadiene Styrene), are harmful to both the environment and human health. However, this is not entirely true.

Fact: There Are Sustainable 3D Printing Materials

While it’s true that some 3D printing materials, like ABS, are not biodegradable and can release harmful chemicals when burned, there are many alternative materials available that are more sustainable. PLA (Polylactic Acid), for example, is derived from renewable resources like corn starch or sugarcane and is biodegradable. Additionally, there are new bio-based and recyclable materials being developed for 3D printing, which help reduce the environmental footprint of the technology. Some 3D printing companies also encourage the use of recycled filament, further decreasing the demand for virgin plastics.

Myth 3: 3D Printing Results in Excessive Plastic Waste

A common myth is that 3D printing contributes significantly to plastic waste due to the use of plastic filaments in the printing process. Critics argue that 3D printing leads to the accumulation of plastic waste because of failed prints, support structures, or unused filament.

Fact: Waste Reduction Through Precision Manufacturing

While it’s true that some plastic waste can result from failed prints or supports, 3D printing offers a level of precision that can reduce material waste compared to traditional manufacturing processes. In traditional manufacturing, excess material is often cut away or discarded, leading to higher waste levels. 3D printing, on the other hand, only uses the exact amount of material needed for the print. Moreover, many 3D printing services offer ways to recycle or reuse waste materials, further mitigating the potential for plastic waste.

Myth 4: 3D Printing Can Only Contribute to Environmental Harm

Some argue that the rise of 3D printing only exacerbates environmental issues by encouraging overconsumption and waste. However, this view overlooks the potential of 3D printing to contribute positively to sustainability efforts.

Fact: 3D Printing Can Foster Sustainability

In many cases, 3D printing can contribute positively to the environment by enabling localized production, reducing the need for transportation, and encouraging more sustainable manufacturing practices. For example, 3D printing allows for on-demand production, which can reduce overproduction and waste in supply chains. Moreover, the ability to print spare parts or products locally reduces the need for long-distance shipping, which helps decrease the carbon footprint associated with transportation. Additionally, in industries like aerospace and automotive, 3D printing allows for lightweight, complex parts that reduce material use and improve energy efficiency.

Conclusion

While there are valid concerns about the environmental impact of 3D printing, it’s important to separate myths from facts to understand the true implications. The energy consumption and material waste associated with 3D printing can be mitigated through careful material selection, recycling efforts, and advancements in technology. Moreover, 3D printing has the potential to promote sustainability by enabling more localized, efficient production processes. As technology continues to evolve, the environmental impact of 3D printing will likely become even more favorable, offering a more sustainable solution for industries and hobbyists alike.