Common 3D Printing Issues and Fixes

- By -Duke

- Posted on

- Posted in 3D Printers

3D printing is an exciting technology, but like any advanced tool, it can come with its fair share of challenges. Whether you’re a beginner or an experienced maker, it’s normal to run into problems from time to time. Understanding common issues and how to fix them will help you improve your print quality and get the most out of your 3D printer. Below are some of the most frequent 3D printing issues and their fixes.

Poor Bed Adhesion

Problem: One of the most common issues in 3D printing is poor adhesion between the first layer of the print and the print bed. This can lead to warping, shifting, or even complete failure of the print.

Possible Causes:

- Uneven or unlevel print bed.

- Dirty print bed surface.

- Incorrect print temperature or bed temperature.

- Insufficient first layer height or speed.

Fixes:

- Level the Print Bed: Ensure the print bed is level. If your printer doesn’t have auto bed leveling, manually adjust the bed using a piece of paper to check for even gaps between the nozzle and the bed.

- Clean the Bed: Use isopropyl alcohol to clean the print bed and remove any oils or dust that could affect adhesion.

- Use Adhesive: Consider using a glue stick, painter’s tape, or a specialized print surface (e.g., BuildTak, PEI sheet) for better adhesion.

- Adjust First Layer Settings: Increase the first layer height, slow down the print speed for the first few layers, or increase the bed temperature for better adhesion.

Warping

Problem: Warping occurs when the corners of your print lift off the bed as the model cools, causing distortion. This is common with certain materials like ABS.

Possible Causes:

- Uneven cooling of the print.

- Insufficient bed adhesion.

- Low bed temperature.

- Printing with materials that shrink as they cool (like ABS).

Fixes:

- Increase Bed Temperature: For materials like ABS, raising the bed temperature to 90–110°C can reduce warping by keeping the first layer warmer for longer.

- Use a Heated Bed: A heated print bed helps prevent warping by ensuring consistent heat distribution during the print.

- Use a Brim or Raft: Adding a brim or raft in your slicer can help prevent warping by increasing the adhesion area of the print.

- Enclose Your Printer: If possible, use an enclosure to maintain a more stable print environment and reduce temperature fluctuations.

Stringing and Oozing

Problem: Stringing happens when small strands of filament are left between parts of the print as the extruder moves from one point to another. This can lead to a messy, unsightly print.

Possible Causes:

- Excessive extrusion.

- High printing temperature.

- Incorrect retraction settings.

- Slow travel speeds.

Fixes:

- Increase Retraction Distance/Speed: Retraction helps pull the filament back into the nozzle to prevent oozing. Increase retraction distance or speed in your slicer settings.

- Lower Print Temperature: Try lowering the nozzle temperature by 5–10°C to reduce the chance of the filament oozing.

- Increase Travel Speed: Faster travel speeds between non-printing areas reduce the time the extruder spends moving across open spaces, minimizing stringing.

- Enable “Combing”: In your slicer, enable combing mode, which prevents the nozzle from crossing open spaces while printing.

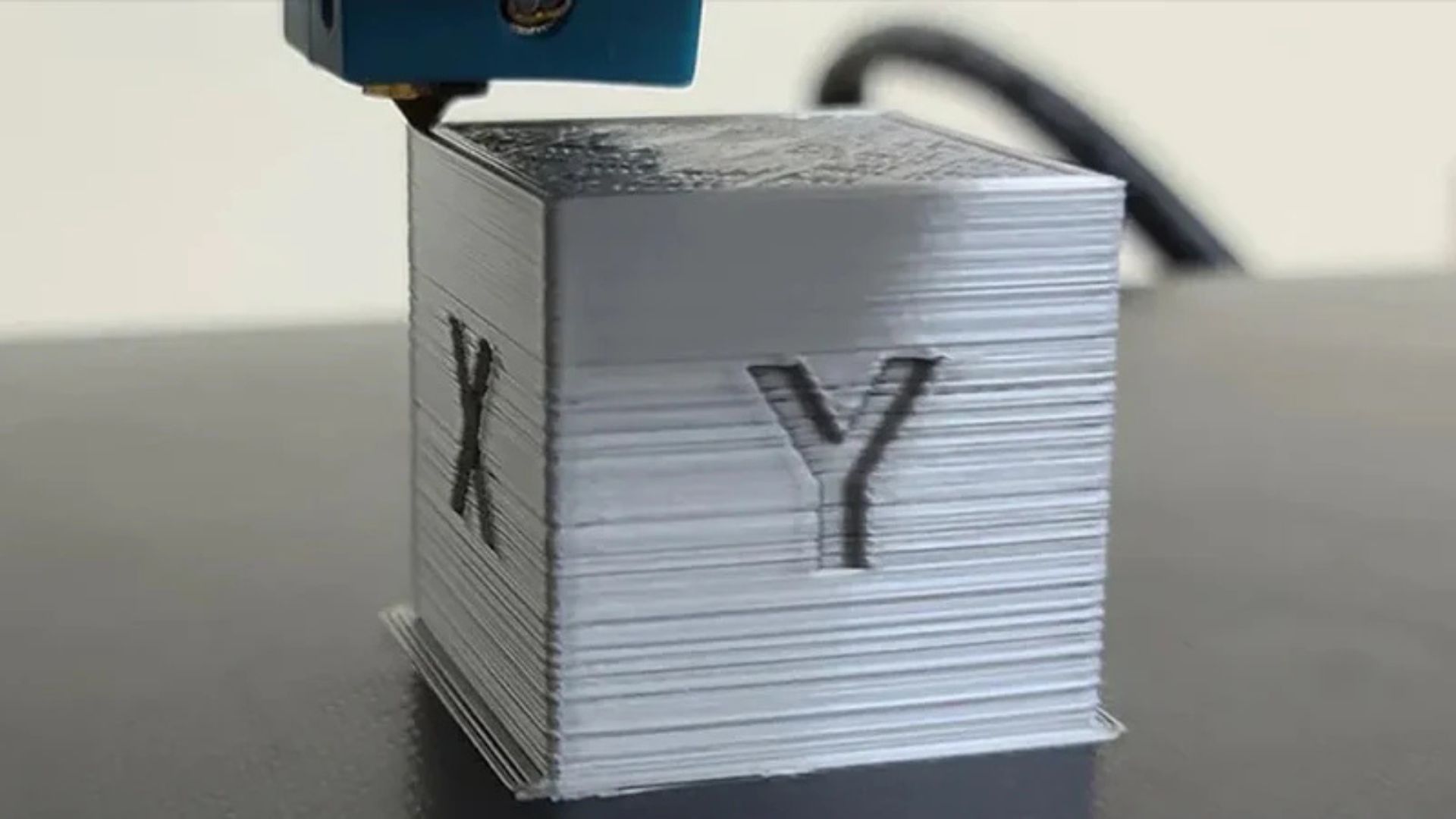

Layer Shifting

Problem: Layer shifting occurs when the printed layers are misaligned, causing a skewed or warped print. This often results in parts of the model being displaced or misaligned.

Possible Causes:

- Loose or misaligned belts.

- Insufficient motor current or weak stepper motors.

- Overheating or mechanical obstruction.

Conclusion

While 3D printing can seem intimidating at times, most issues are fixable with some troubleshooting and adjustments. By understanding common problems like poor adhesion, warping, stringing, and layer shifting, you can quickly improve your print quality and ensure smoother printing experiences. Whether you’re a beginner or an experienced user, learning how to troubleshoot these common 3D printing problems will help you maximize the potential of your 3D printer and get the results you want.