How 3D Printers Are Revolutionizing Manufacturing

- By -Duke

- Posted on

- Posted in 3D Printers

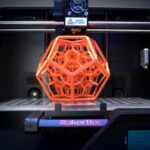

D printing, or additive manufacturing, is changing the way products are designed, produced, and delivered. This technology builds objects layer by layer from digital models, offering benefits like lower costs, faster production times, and increased design flexibility. In this article, we explore how 3D printing is revolutionizing the manufacturing industry.

What is 3D Printing?

At its core, 3D printing is a process where material is deposited layer by layer to create an object. Unlike traditional manufacturing methods like machining or molding, 3D printing is additive. This means it only uses the material necessary for the part, leading to less waste.

Several types of 3D printing technologies exist, such as FDM (Fused Deposition Modeling), SLA (Stereolithography), and SLS (Selective Laser Sintering). Each has unique benefits, but all share the core concept of building objects in layers.

Faster Production and Reduced Lead Times

In traditional manufacturing, creating prototypes and tooling can take weeks or months. With 3D printing, manufacturers can produce prototypes in just hours or days. This drastic reduction in time allows companies to test and modify designs quickly, speeding up the development process.

Moreover, 3D printing eliminates the need for expensive molds or tooling. As a result, the overall lead time from concept to finished product is significantly shorter. Manufacturers can go from digital design to physical prototype in a matter of hours.

Cost Efficiency

3D printing reduces costs in several ways. First, it minimizes material waste. Traditional methods like machining cut away material from a larger block, while 3D printing only uses the exact amount needed. This efficiency lowers production costs and reduces environmental impact.

Customization and Design Flexibility

3D printing offers unprecedented design flexibility. Designers can create intricate shapes and complex geometries that would be impossible or prohibitively expensive using traditional methods. This is particularly valuable in industries like aerospace, healthcare, and automotive, where lightweight, customized, and highly specialized parts are often required.

On-Demand Production and Local Manufacturing

One of the most exciting aspects of 3D printing is its ability to enable on-demand production. Instead of mass-producing items and storing large inventories, manufacturers can print products only when they are needed. This reduces storage costs and helps companies better manage supply chains.

Impact on Supply Chains

3D printing is transforming traditional supply chains. By producing parts and products on-site, manufacturers can reduce dependency on suppliers and third-party vendors. This helps businesses respond quickly to changes in demand, minimize stockouts, and avoid overstocking.

Sustainability Benefits

The environmental impact of manufacturing is a growing concern. 3D printing offers several sustainability benefits. First, it reduces material waste since it only uses the exact amount of material needed. This contrasts sharply with traditional methods, which often result in a significant amount of waste.

Advancements in Materials

Another area where 3D printing is advancing is materials. Initially, 3D printers were limited to basic plastics, but today, a wide range of materials is available. These include metals, ceramics, composites, and even bio-materials like human tissue.

The Future of 3D Printing in Manufacturing

Looking ahead, the role of 3D printing in manufacturing will only continue to grow. As technology advances, 3D printers will become faster, more accurate, and capable of using even more diverse materials. The continued rise of AI and machine learning will further enhance the capabilities of 3D printing, allowing for smarter design, production, and quality control.

Conclusion

3D printing is revolutionizing manufacturing by offering faster production, cost savings, greater customization, and sustainability. With its ability to transform design processes, streamline supply chains, and reduce environmental impact, it is clear that 3D printing will continue to shape the future of manufacturing across industries.

As businesses adopt this technology, the innovation potential is limitless. Whether in prototyping, on-demand production, or highly customized goods, 3D printing is paving the way for a new era in manufacturing.