How 3D Printing Enhances Product Prototyping

Product prototyping is a crucial step in the development of new products, allowing designers and manufacturers to test, refine, and perfect their designs before full-scale production. Traditional methods of prototyping can be expensive, time-consuming, and often lack precision. However, 3D printing has revolutionized the prototyping process, providing significant benefits that enhance design accuracy, reduce costs, and speed up the overall process.

Cost Reduction in Prototyping

Traditionally, creating product prototypes involved costly materials and labor. Prototypes often required mold creation, tool setup, and multiple iterations before achieving the desired result. 3D printing eliminates the need for these expensive processes, as it allows companies to produce prototypes directly from digital designs. This significantly reduces the cost per iteration, making it possible to create multiple prototypes in a short period without incurring high costs.

Faster Iterations and Testing

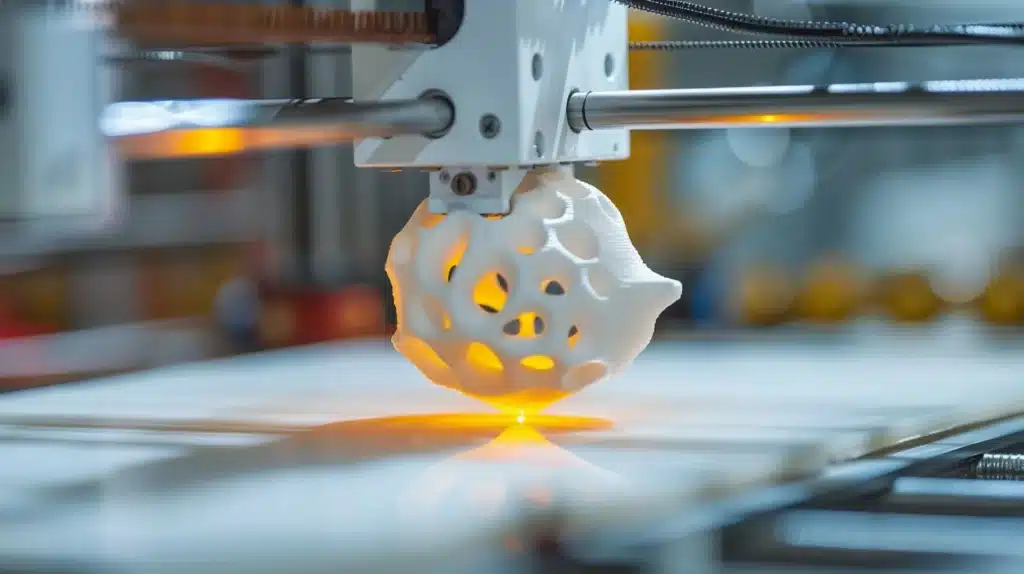

3D printing allows businesses to quickly produce multiple versions of a prototype and make adjustments based on real-world testing. Traditional prototyping methods can take weeks to produce a single iteration, especially if complex molds or tooling are required. With 3D printing, prototypes can be printed in a matter of hours, enabling faster testing, feedback, and refinement. This rapid iteration process accelerates the product development timeline and allows for more design tweaks and improvements.

Enhanced Design Flexibility

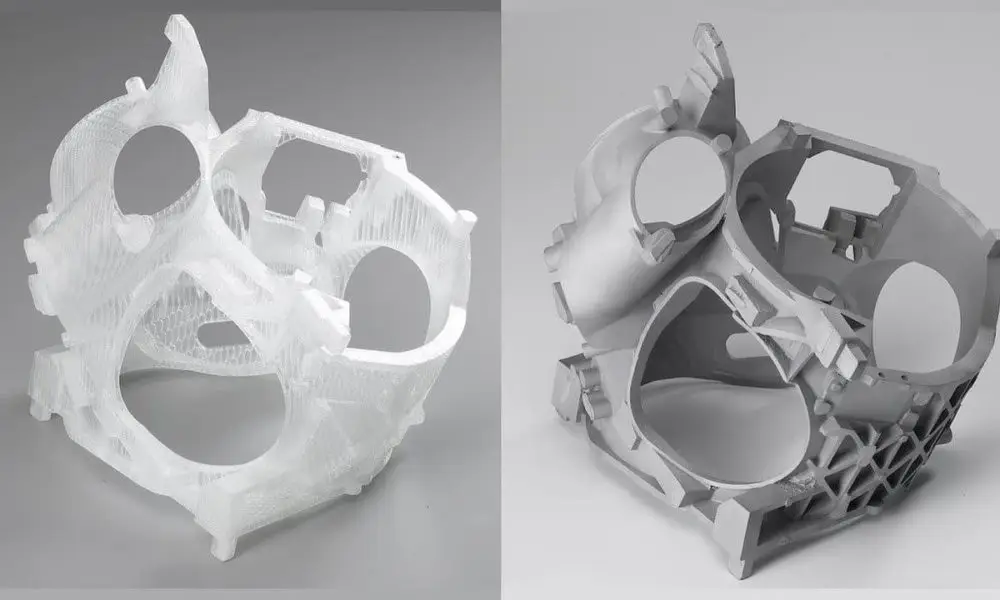

One of the key advantages of 3D printing is its ability to handle highly complex and intricate designs that would be difficult or impossible to achieve using traditional methods. Designers can create prototypes with detailed geometries, internal structures, and moving parts that are not easily produced through conventional techniques. 3D printing enables designers to explore a wide range of creative possibilities and experiment with innovative features, ensuring that the final product meets both functional and aesthetic requirements.

Improved Design Accuracy

3D printing enhances design accuracy by allowing designers to print prototypes directly from CAD (Computer-Aided Design) files. This reduces the risk of human error during the manufacturing process and ensures that the prototype is an accurate representation of the final product. Moreover, 3D printers are capable of producing precise, detailed models with a high degree of dimensional accuracy, making it easier to test for fit, form, and function before committing to mass production.

Prototyping Complex Parts with Less Waste

Traditional prototyping methods often involve subtracting material from a larger block, resulting in wasted material. In contrast, 3D printing is an additive manufacturing process, meaning material is deposited layer by layer only where needed. This minimizes waste and allows for the efficient use of materials, reducing both costs and environmental impact. The ability to print prototypes with minimal waste is particularly beneficial for businesses looking to keep costs down and operate sustainably.

Customization and Personalization

With 3D printing, businesses can easily create customized or personalized prototypes tailored to specific customer needs. Whether it’s altering the size, shape, or material properties of a prototype, 3D printing offers a level of flexibility that traditional methods cannot match. This ability to quickly adjust and customize prototypes is especially useful in industries such as healthcare, where products may need to be tailored for individual patients, or in consumer goods, where customer preferences can vary widely.

Collaboration and Communication Enhancement

3D printing enables better collaboration and communication during the prototyping phase. Designers, engineers, and stakeholders can review a physical prototype in real-time, which improves the decision-making process. Instead of relying solely on 2D drawings or digital models, teams can physically interact with prototypes, providing more valuable insights and feedback. This hands-on approach fosters better teamwork and ensures that potential issues are identified and resolved early in the design process.

Reducing Time to Market

The ability to produce accurate prototypes quickly and affordably can drastically reduce the time it takes to bring a product to market. By streamlining the prototyping process, companies can test, iterate, and finalize their designs faster, speeding up the overall development timeline. This reduction in time to market gives businesses a competitive edge, allowing them to launch new products before their competitors and respond quickly to market trends.

Conclusion

3D printing has transformed the prototyping process, providing businesses with numerous benefits, including cost reduction, faster iterations, and improved design flexibility. By enabling rapid testing and refinement, 3D printing accelerates product development and allows for more innovative and accurate designs. With its ability to minimize waste, enhance customization, and reduce time to market, 3D printing is an indispensable tool for modern product prototyping. As the technology continues to advance, its role in shaping the future of product development will only grow.