The Evolution of 3D Printing Technology

3D printing technology has grown from a niche innovation to a transformative tool in various industries. What started as a method for rapid prototyping is now a mainstream technology used in manufacturing, healthcare, and even personal projects. Let’s explore how 3D printing evolved and became a part of everyday life.

1. The Beginnings of 3D Printing

In the 1980s, 3D printing emerged as stereolithography (SLA). Charles Hull patented the process, which used UV light to harden layers of liquid resin. This innovation made it possible to create complex prototypes quickly and revolutionized product development.

2. Early Applications in Prototyping

Throughout the 1990s, companies adopted 3D printing to develop prototypes. Engineers could now test designs faster and reduce production costs. Industries like automotive and aerospace became early adopters, creating parts with precision and speed.

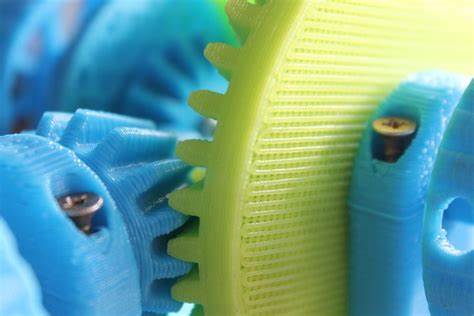

3. Advances in Materials and Techniques

The 2000s saw breakthroughs in materials and printing methods, including:

- Selective Laser Sintering (SLS): This method fused powdered materials with lasers to create durable parts.

- Fused Deposition Modeling (FDM): A technique using thermoplastics, ideal for creating affordable 3D-printed objects.

These advancements allowed 3D printing to expand beyond prototyping into functional applications.

4. Adoption in Healthcare

One of the most transformative applications of 3D printing emerged in medicine. By the 2010s, the technology was used to create:

- Custom prosthetics and orthotics.

- Implants tailored to individual patients.

- 3D-printed models for surgical planning.

This revolutionized patient care by offering personalized and cost-effective solutions.

5. The Rise of Consumer 3D Printers

The introduction of affordable desktop 3D printers in the mid-2010s brought the technology to hobbyists and small businesses. Brands like MakerBot and Prusa made it possible for anyone to print objects at home, from tools to decorative items.

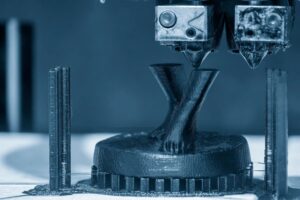

6. 3D Printing in Manufacturing

Industries began incorporating 3D printing into production lines for creating end-use parts. Advantages included:

- Reduced waste compared to traditional methods.

- Faster production cycles for customized products.

- On-demand manufacturing, eliminating the need for large inventories.

7. Sustainability and Eco-Friendly Innovations

3D printing has also contributed to sustainability efforts. Many manufacturers now use recycled materials or biodegradable filaments to reduce their environmental impact. Additionally, the ability to produce only what is needed minimizes waste.

8. Emerging Applications in Everyday Life

Today, 3D printing impacts everyday life in various ways, including:

- Education: Schools use 3D printers to teach STEM skills and foster creativity.

- Fashion: Designers create unique accessories and garments using printed materials.

- Food: Chefs experiment with printing edible designs, reshaping culinary experiences.

9. The Future of 3D Printing

As technology continues to evolve, the future of 3D printing looks promising. Emerging trends include:

- Bioprinting: The creation of organs and tissues for medical transplants.

- Construction: Printing homes and structures with concrete-based materials.

- Space Exploration: Producing tools and parts on-demand in space missions.

Conclusion

3D printing has transitioned from an experimental technology to a versatile tool shaping various aspects of life. Its evolution demonstrates the potential of innovation to transform industries and enhance everyday experiences.