The Future of Manufacturing with 3D Printers

- By -Duke

- Posted on

- Posted in 3D Printers

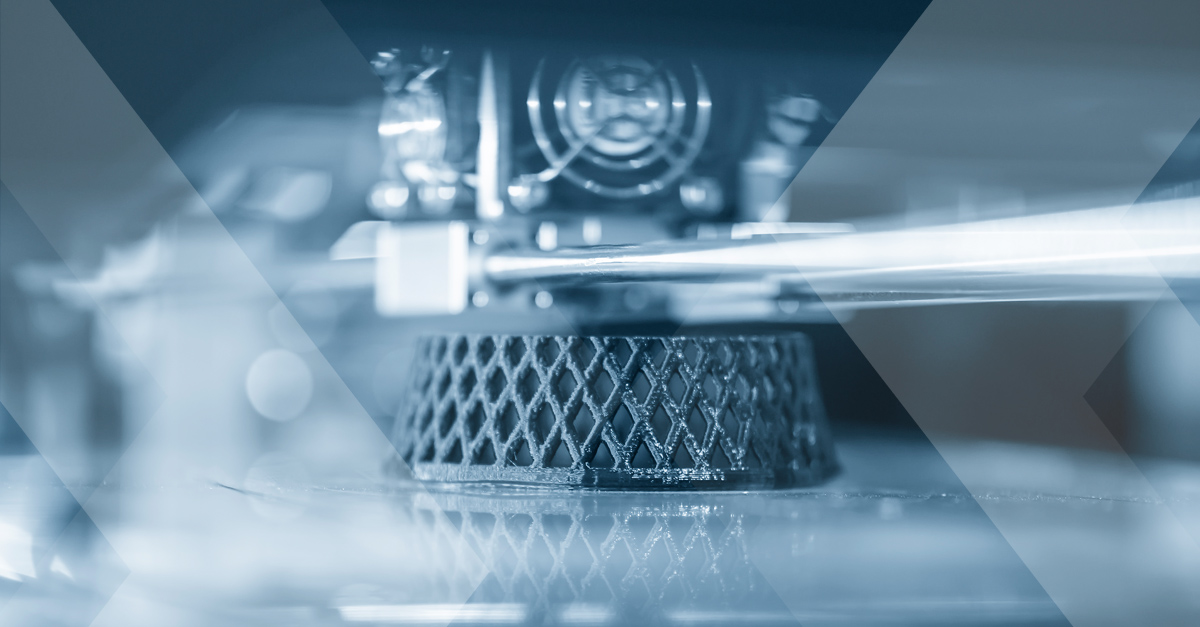

The manufacturing industry evolves rapidly, and 3D printing leads this transformation. This revolutionary technology changes how products are designed and made. It offers speed, efficiency, and customization, making traditional manufacturing methods seem outdated.

How 3D Printers Revolutionize Manufacturing

3D printing enables manufacturers to create complex designs effortlessly. Traditional methods often struggle with intricate geometries. However, 3D printers handle these challenges efficiently. They allow for creating prototypes and end-use products directly from digital designs.

The ability to produce on demand reduces the need for large inventories. Companies print only what they need, saving storage space and cutting costs. This flexibility gives businesses a competitive edge.

Customization Made Simple

Customization becomes effortless with 3D printing. Companies can tailor products to individual needs without increasing costs significantly. For example, in the medical field, 3D printers create custom prosthetics and implants that fit perfectly.

Similarly, the automotive and aerospace industries benefit from tailored parts. These industries demand precision, and 3D printers deliver with ease. This approach ensures better performance and reduced waste.

Reducing Waste and Supporting Sustainability

Sustainability becomes increasingly important in manufacturing. Traditional methods often generate significant material waste. In contrast, 3D printing uses only the material needed. This process minimizes waste, making it an eco-friendly solution.

Moreover, 3D printing encourages local production. Products are manufactured closer to their point of use, reducing the carbon footprint from transportation. This local approach also shortens supply chains, enhancing efficiency.

Speeding Up Production Timelines

Time-to-market is critical in today’s fast-paced industries. 3D printers speed up production timelines by eliminating multiple steps in traditional methods. Prototyping, which previously took weeks, now happens within hours.

This speed allows companies to test and refine products quickly. It also enables manufacturers to respond faster to market demands and stay ahead of competitors.

Applications Across Various Industries

3D printing impacts diverse industries significantly. In healthcare, it produces surgical tools, implants, and even organ models for practice. In construction, 3D printers create homes and bridges faster and more efficiently.

The fashion industry also embraces this technology. Designers experiment with 3D-printed clothing and accessories, pushing creative boundaries. The possibilities seem limitless as more industries adopt this versatile tool.

Challenges and the Road Ahead

Despite its advantages, 3D printing faces challenges. High initial costs deter smaller companies from investing in the technology. Additionally, the limited availability of materials restricts its application in some fields.

However, advancements continue to address these issues. Material innovations and cost reductions make 3D printing more accessible. As these challenges diminish, its adoption will increase further.

Conclusion

The future of manufacturing lies in 3D printing. Its ability to produce complex, customized, and sustainable products reshapes industries worldwide. With ongoing innovations, 3D printing continues to overcome barriers and expand its potential.

As this technology evolves, it promises a future where production is faster, smarter, and more sustainable. Embracing 3D printing ensures businesses remain competitive in this ever-changing landscape.