The Role of 3D Printing in Space Exploration

- By -Duke

- Posted on

- Posted in 3D Printers

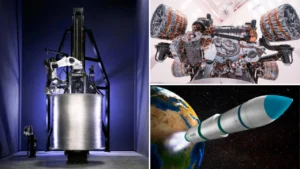

3D printing, also known as additive manufacturing, is making waves in many industries, and space exploration is no exception. In the harsh and unpredictable environment of space, traditional manufacturing methods often face limitations, especially when it comes to transporting materials and equipment. However, 3D printing offers innovative solutions to these challenges. By enabling the creation of objects directly in space, it reduces dependency on Earth-based supply chains, providing astronauts with more autonomy. In this article, we will explore the role of 3D printing in space exploration and its potential to revolutionize the future of space missions.

Reducing Dependence on Earth-Based Supplies

One of the most significant challenges of space exploration is the cost and complexity of transporting supplies from Earth to space. Every kilogram sent to space requires extensive fuel and resources, making it expensive and logistically difficult. Traditional methods rely on pre-manufactured parts, which must be stored and transported in spacecraft. 3D printing addresses this challenge by allowing astronauts to manufacture tools, parts, and even habitats directly in space. This capability reduces the need to bring every item from Earth, enabling space missions to become more self-sufficient.

Fact: Printing Tools and Parts in Space

NASA’s experiments with 3D printing aboard the International Space Station (ISS) have already shown promising results. In 2014, NASA sent a 3D printer to the ISS as part of the “Made in Space” initiative. Since then, astronauts have printed various items, including tools, replacement parts, and even small mechanical components. This technology allows astronauts to fabricate exactly what they need when they need it, eliminating the need for resupply missions and providing a greater level of flexibility during long-term space missions.

Enhancing Spacecraft and Habitat Construction

In addition to producing tools and spare parts, 3D printing has the potential to play a vital role in spacecraft and habitat construction. Creating large structures in space is a complicated and resource-intensive process, often requiring multiple launches and heavy lifting. 3D printing offers a more efficient and cost-effective way to construct habitats and even entire spacecraft. Through the use of advanced materials and 3D printing techniques, these structures can be designed to withstand the harsh conditions of space while being lighter and more adaptable than traditional designs.

Fact: 3D Printing Lunar and Martian Bases

NASA is also exploring the use of 3D printing for constructing habitats on the Moon and Mars. By utilizing local materials, such as regolith (lunar soil), astronauts could print building materials directly on the Moon or Mars. This method would not only reduce the need to transport building materials from Earth but also make it possible to create durable, sustainable shelters that are specifically designed to withstand the extreme temperatures and radiation of space. The development of 3D-printed lunar and Martian bases is a significant step forward in the quest for long-term human habitation on other planets.

Customized Solutions for Astronauts

Another key benefit of 3D printing in space exploration is its ability to create customized solutions for astronauts. In space, the unique needs and preferences of individual crew members can vary, and medical supplies or personal items may not always be readily available. 3D printing offers the possibility of creating personalized tools, medical devices, and even food containers tailored to the specific needs of astronauts.

Fact: Personalized Medical Equipment in Space

One such application is the creation of customized medical equipment. If astronauts encounter a medical issue during a mission, 3D printing can be used to create personalized devices or tools to assist in treatment. For example, if an astronaut requires a specialized medical device, it can be designed and printed on demand, reducing the need to carry a vast array of supplies. This capability could be particularly valuable on long-duration missions to Mars or deep space, where resupply missions would be infrequent or impossible.

Sustainability and Recycling in Space

Sustainability is another crucial aspect of 3D printing in space exploration. As space missions extend beyond low Earth orbit, sustainability becomes increasingly important. 3D printing allows for the recycling of materials, such as plastic waste, into usable filament for printing. This reduces the reliance on bringing new materials from Earth and minimizes the accumulation of waste in space. Recycling and reusing materials could play a pivotal role in ensuring that long-term missions remain sustainable.

Fact: Recycled Materials in Space Printing

NASA’s efforts to incorporate recycling into space exploration have already begun. For instance, some 3D printers are being designed to work with recycled materials, allowing astronauts to reuse waste from everyday operations. This recycling process is especially important for missions to Mars or further destinations, where resources would be limited, and sustainability is crucial.

The Future of 3D Printing in Space Exploration

The future of 3D printing in space exploration is filled with exciting possibilities. As technology continues to evolve, 3D printing will likely become even more integral to the design, construction, and maintenance of space missions. Innovations such as the use of new materials, greater automation, and improved recycling techniques will further enhance the capabilities of 3D printing in space.

Moreover, as commercial space companies continue to push the boundaries of space exploration, they will likely play a significant role in developing new 3D printing technologies for use in both private and government space missions. The integration of 3D printing could eventually allow humanity to build sustainable colonies on other planets, paving the way for a new era of space exploration.

Conclusion

3D printing has proven to be a valuable tool in space exploration, offering numerous benefits ranging from reduced dependence on Earth-based supplies to the ability to build habitats and spacecraft directly in space. As technology advances, the role of 3D printing in space exploration will only continue to grow, providing innovative solutions for long-term space missions. By enabling astronauts to create customized tools, recycle materials, and construct habitats on other planets, 3D printing is helping to shape the future of space exploration, making it more sustainable, efficient, and self-sufficient.