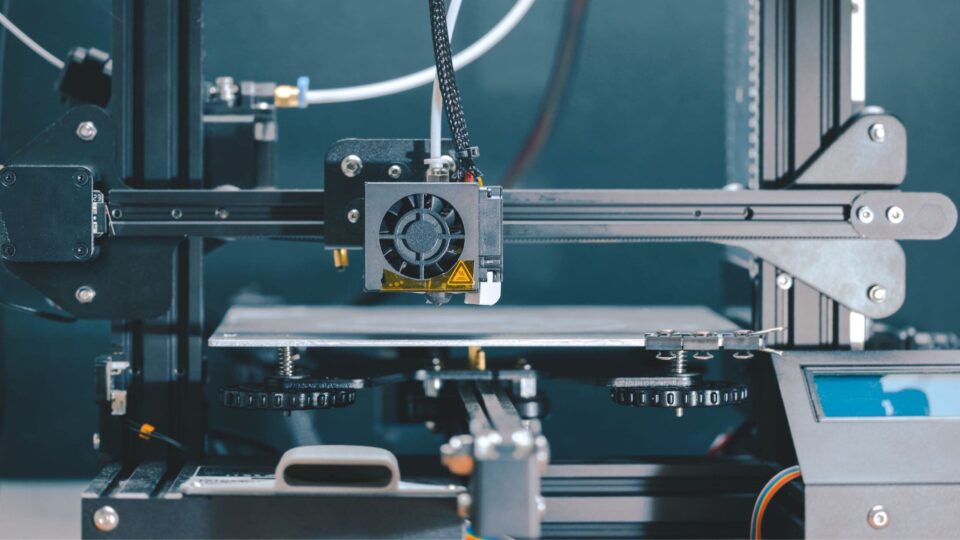

Tips for Maintaining Your 3D Printer for Longevity

3D printers are versatile tools that can create everything from intricate prototypes to functional parts. However, like any machine, they require regular maintenance to perform optimally and last longer. By following these tips, you can keep your 3D printer in excellent condition for years to come.

1. Regular Cleaning

Nozzle Maintenance

The nozzle can accumulate residue and clogs over time. To maintain consistent extrusion:

- Clean the nozzle: Use a wire brush or cleaning filament regularly.

- Unclog stubborn blockages: Heat the nozzle and carefully use a needle or pin to remove obstructions.

Build Plate Care

A clean build plate ensures proper adhesion and successful prints:

- Remove filament residue with isopropyl alcohol.

- Avoid scratches by using a scraper with care.

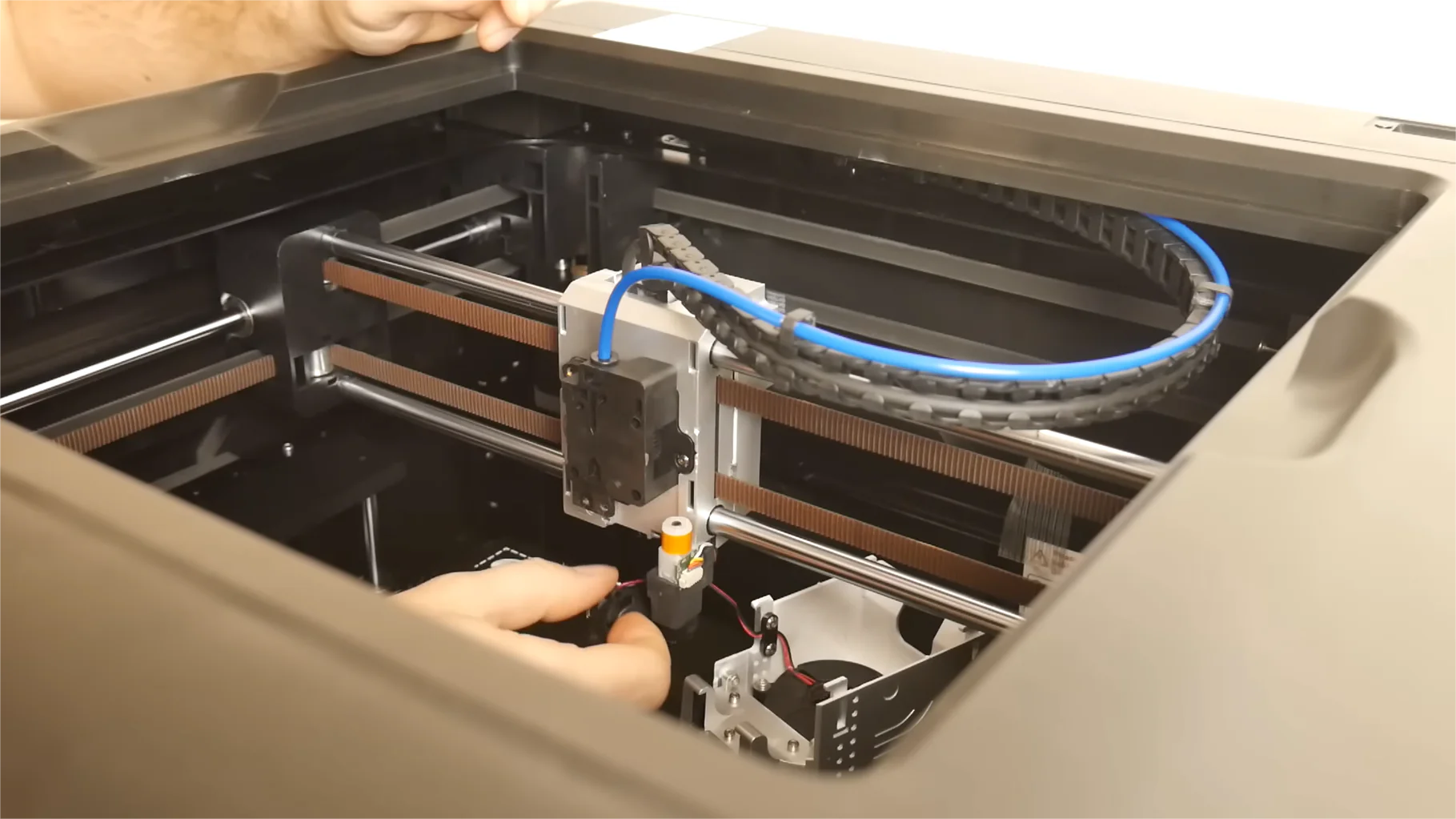

2. Lubricate Moving Parts

Your printer’s moving components, such as rails and lead screws, need lubrication to reduce friction and wear:

- Use a light machine oil or grease recommended by your printer manufacturer.

- Avoid over-lubricating, as excess oil can attract dust.

3. Inspect Belts and Pulleys

Belts control the movement of your printer’s axes and must remain taut for accurate prints:

- Check belt tension: Tighten loose belts to avoid layer shifting.

- Inspect for wear: Replace belts that show fraying or damage.

4. Level the Bed Regularly

Bed leveling is crucial for adhesion and print accuracy:

- Perform bed leveling before starting any major print project.

- For manual printers, use a piece of paper or feeler gauge to check the gap between the nozzle and bed.

- Consider upgrading to an auto-leveling sensor for consistent results.

5. Update Firmware

Printer manufacturers often release firmware updates to improve performance and fix bugs:

- Check for updates on the manufacturer’s website.

- Follow the update instructions carefully to avoid damaging the printer.

6. Monitor and Replace Worn Components

Over time, some parts will naturally wear out:

- Extruder gear: Inspect for filament grinding or worn teeth.

- Fans: Ensure cooling fans are dust-free and spinning efficiently.

- Build surface: Replace when adhesion diminishes significantly.

7. Calibrate for Accuracy

Regular calibration ensures your printer produces high-quality prints:

- X, Y, and Z axes: Check alignment using a calibration cube or test print.

- Extruder steps: Measure and adjust the extrusion rate to prevent over- or under-extrusion.

8. Manage Filament Storage

Filament can degrade if exposed to moisture:

- Store filament in a sealed container with silica gel packets.

- Use a filament dryer for long-term storage or during humid conditions.

9. Keep Electronics Safe

Electrical components, such as wires and connectors, are vital to your printer’s operation:

- Check connections: Ensure all wires are secure and free from damage.

- Inspect the power supply: Listen for unusual noises or check for excessive heat.

10. Schedule Routine Maintenance

Create a regular maintenance schedule based on your printer’s usage:

- Weekly: Clean the nozzle, check belts, and remove filament residue.

- Monthly: Inspect for wear, lubricate moving parts, and calibrate axes.

- Quarterly: Deep-clean the printer, replace worn components, and update firmware.

Conclusion

Proper maintenance is essential to keep your 3D printer running smoothly and extending its lifespan. By adopting these tips, you can ensure consistent print quality, minimize downtime, and protect your investment. Regular care not only saves money on repairs but also enhances your overall 3D printing experience.

Start maintaining your printer today, and enjoy flawless prints for years to come!